Microsilica, or silica fume, is an amorphous type of silica dust mostly collected in baghouse filters as by-product of the silicon and ferro-silicon production.

Microsilica consists of spherical particles with an average particle size of 150 nm and a specific surface area of typically 20 m2/g. The chemical and physical properties of this inorganic product are different as compared to other amorphous and crystalline silica polymorphs. More than 500.000 MT of microsilica are sold to the building industry world-wide and are used in fibre cement, concrete, oil-well drilling, refractories, and even in polymers.

In order to tailor or enhance concrete properties for specific applications, a multitude of concrete additives is available on the market. Among these are also pozzolans. According to ASTM C618, pozzolans are defined as “siliceous or siliceous and aluminous material which, in itself, possesses little or no cementitious value but which will, in finely divided form in the presence of moisture, react chemically with calcium hydroxide at ordinary temperature to form compounds possessing cementitious properties”. Typical pozzolans are for example volcanic ashes, mineral slag, fly ash, and silica fume.

Due to unique chemical and physical properties, microsilica has become a versatile mineral admixture for a multitude of applications.

Apart from its use in construction concrete for tunnels, bridges, parking structures and skyscrapers, the use of microsilica in non-asbestos fibre cement enhances bending strength and density, while it reduces porosity and water absorption. This has a positive effect on the freeze-thaw properties.

Furthermore, microsilica is a key ingredient in refractories, and special grades are even used as impact modifier and process aid in polymers.

Fibre cement additive – Silica fume

Fibre cement additive – Silica fume

Microsilica Grade 920 for Fibre Cement:

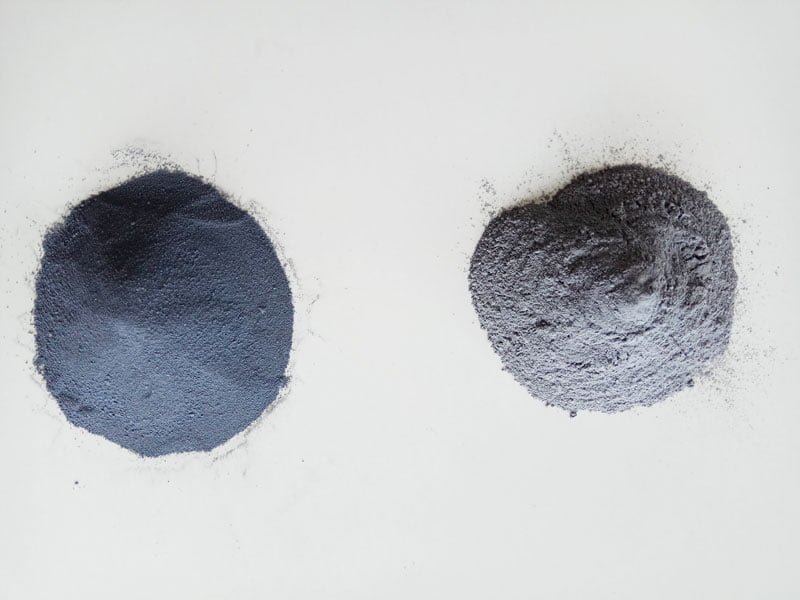

Microsilica Grade 920 is a dry silica fume available in two main forms. Undensified and Densified. In use, it acts physically as an interactive filler and chemically as a highly reactive pozzolan. A key ingredient in many construction materials, Microsilica is used in fibre cement products as a process aid, to improve ingredient dispersion and to improve hardened properties and overall durability.

Undensified Silica fume 920U information: https://microsilica-fume.com/product/92-undensified-microsilica-fume.html

Densified Silica fume 920D information: https://microsilica-fume.com/product/92-silica-fume.html

Microsilica Grade 940 for Fibre Cement:

Microsilica Grade 940 is a dry silica fume available in two main forms: Undensified (U) and Densified (D). In use, it acts physically as a filler and chemically as a highly reactive pozzolan. A key ingredient in many construction materials, Microsilica is used in fibre cement products as a process aid, to improve ingredient dispersion and to improve hardened properties and overall durability.

Undensified Silica fume 940U information: https://microsilica-fume.com/product/94-undensified-silica-fume.html

Densified Silica fume 940D information: https://microsilica-fume.com/product/94-silica-fume.html

Packaging & Delivery

10kg soluble paper bags x 84 on the pallets.

20kg soluble paper bags x 42 on the pallets.

950kg plastic woven bags x 2 on the pallets(with or without bottom output )

1000kg plastic woven bags x 2 on the pallets(with or without bottom output )

500kg plastic woven bags x 2 on the pallets (with or without bottom output )

We can also produce according to your requirement.

Storage & handling

Microsilica Grade 920 should be stored in dry conditions and not exposed to moisture.