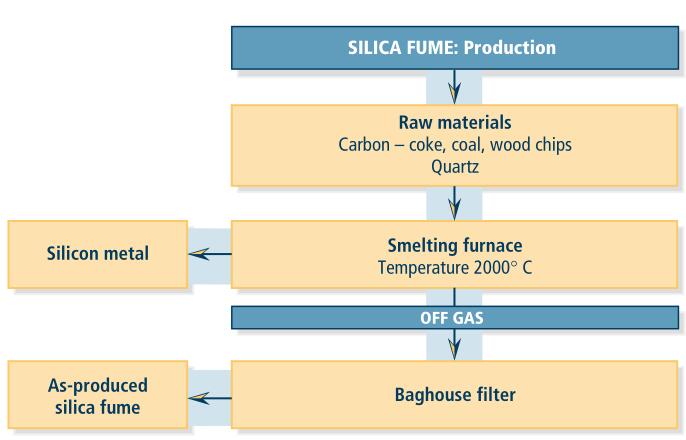

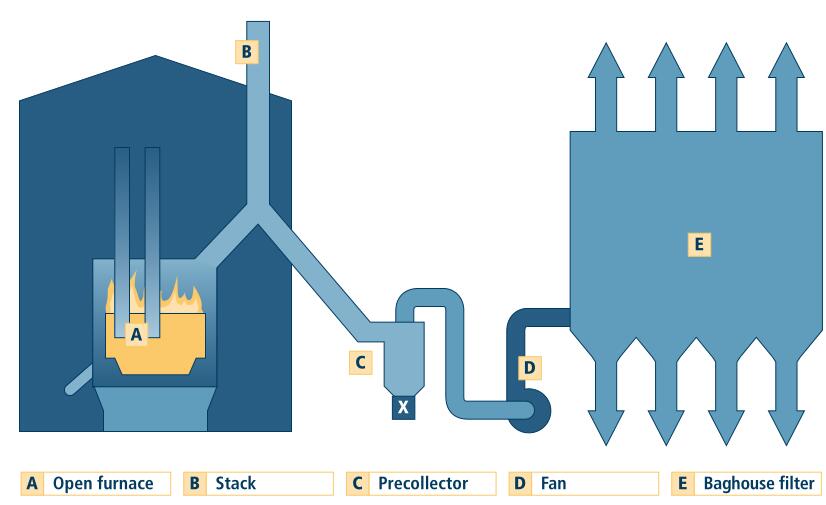

Silica fume is a by-product of producting silicon metal or ferrosilicon alloys in smelters using electric arc furnaces. These metals are used in many industrial applications to include aluminum and steel production, computer chip fabrication, and production of silicons, which are widely used in lubricants and sealants. While these are very valuable materials, the by-product silica fume is more importance to the concrete industry.

Microsilica production:

Microsilica 600 is highly reactive pozzolan and falls into the amorphous silica family of products but has significant advantages over silica fume.

Microsilica 600 meets the requirements detailed in AS/NZS3582.3. Microsilica 600 can be used to enhance a number of hardened concrete properties and is used to develop concretes that provide significant improvement in durability or strength.

The microsilica 600 advantages:

– Very low chloride ion diffusion

– Increased compressive strength

– Reduced water permeability

– Improved sulphate resistance

– Improved abrasion resistance

– Improved resistance to chemical attack

– Improved stability in geothermal environments

– Reduced efflorescence

Packaging & Delivery

10kg soluble paper bags x 84 on the pallets.

20kg soluble paper bags x 42 on the pallets.

950kg plastic woven bags x 2 on the pallets(with or without bottom output )

1000kg plastic woven bags x 2 on the pallets(with or without bottom output )

500kg plastic woven bags x 2 on the pallets (with or without bottom output )

We can also produce according to your requirement.

Technical parameter:

| Property | Units | Microsilica 600 |

| Relative Density | t/m3 | 2.23 |

| Bulk Density – Aerated | kg/m3 | 640 |

| Bulk Density – Non Aerated | kg/m3 | 650 |

| SiO2 Content | % | 86 |

| SiO2 + Al203 Content | % | 91 |

| Relative Strength | % | 114 |

| Passing 2 micron | % | 58 |

For more information, please contact us by E-mail sales@superior-abrasives.com or directly leave your message on the following form, we will reply you in 24h, thank you.