First, silica fume (microsilica) has strong volcanic ash activity. Although the water is not directly added to the silica fume and cannot water hydration reaction, but the wollastonite (micro silica) and cement also added to water, when the cement hydration reaction, silica fume (micro silica) and Ca(OH)2 (one of cement hydration products) immediately occurred twice hydration reaction(i.e. volcano ash reaction), generation C-S-H gel, which consumes Ca (OH) 2 in hydration cement paste, and C-S-H gel( formation volcano reaction) increase and silica fume and another kind of hydration products C-S-H gel in the hydration cement paste (also called traditional C-S-H gel) react, produce new C-S-H gel with low Ca/Si ratio (also known as volcano ash C-S-H gel). The composition and properties of volcano C-S-H gel and traditional C-S-H gel are not the same, it can polymerize the hydroxyl ion and aluminum ion, and polymerization are quite stable. The new generation of C-S-H gel does not decompose in acidic solution, which is prepared using silica fume cement paste body has certain resistance to acidic medium, causes strong resistance to carbonation, dialysis, efflorescence.

In addition, in the interfacial transition zone of concrete, Ca (OH) 2 and Ettringite have orientation, and the interfacial transition zone of crystal is thicker than crystal in hardened cement paste, has more pores, and the cement slurry’s bleeding is relatively high, the water in the cement paste migrate up and in the process will form a water film below the aggregate, weaken the adhesion, forming micro crack of interfacial transition zone.

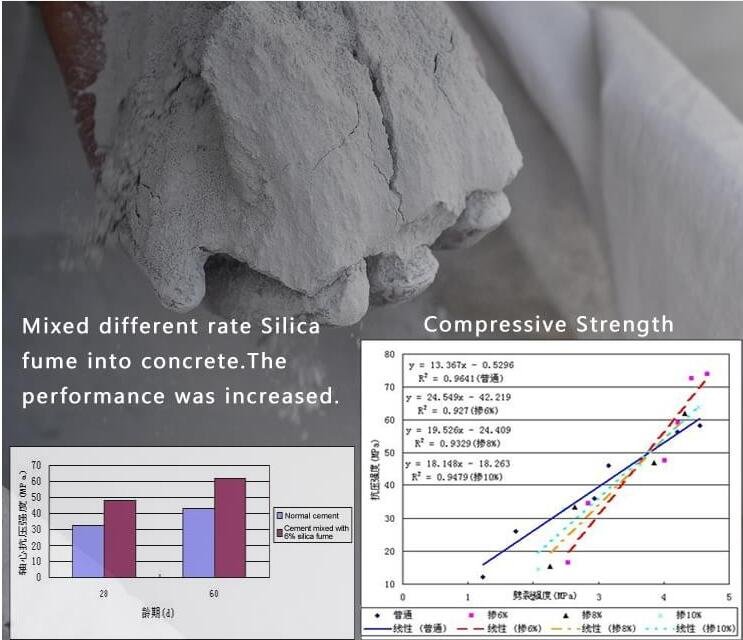

In the gel soil of silica fume, because the reaction consumes most of the Ca (OH) 2, and the traditional C-S-H coagulation translate into ash C-S-H gel, at the same time, due to the great specific surface area of silica fume, can absorb a large amount of free water and reduce bleeding, reduce the free water gather in the aggregate interface, making the interface area structure dense, at the same time, Ca (OH) 2 crystal growth is restricted, the grains are refined, reduce the degree of orientation arrangement, so that the micro structure of interface transition zone improvement. Secondly, because the silica fume particle sizes are smaller, the average particle size is about 0.1μM, is about 1/100 of Portland cement particle size, while silica fume surface area is very large, the specific surface area of silica fume can up to 20m2/g by nitrogen adsorption method, so silica fume is very easy to agglomerate, so it can be as the nuclei needed by the hydration of cement during cement hydration, thus accelerating the hydration of cement. At the same time, due to silica fume has fine particles, it can fill the pores in hardened cement paste, thereby reducing the porosity of cement paste, and then make the hardened cement paste and concrete is more compact, higher strength, and enhance the hardened cement paste and concrete resistance force deformation, so that hardened cement paste and concrete shrinkage reduce.