The common cement concrete is used to repair the pavement and plate. The defect is the low joint strength of the new and old cement concrete, the slow growth of strength and the long blocking of traffic. As a result, ordinary road surface and plate repairing do not accept ordinary concrete.

(1) fast hardened Portland cement concrete

In the preparation of rhpc, add a amount of CaF2, CaSO4, TiO2, Bao, P2O5, MnO and Cr2O3 in raw material, the clinker mineral composition has a great difference with ordinary cement, C3S content is high, still beneficial to early strength 11CaO·7Al2O3 ·CaF2 , 3CaO·3Al2O3 ·CaSO4. The C2S content is relatively small. When the environment temperature is 5-20 ℃, about 3 D can be put into use, 20-30 ℃, 1-2 D can be put into use, but as same with ordinary cement, dry shrinkage is large, new and old cement concrete cementation is poor, because the initial hydration is fast, high internal temperature of cement concrete, so it should pay attention to maintenance, and avoid high temperature construction.

(2) Super early strong cement of sulphoaluminate and fast hardening fast cement of fluoro aluminate

The critical factors of sulphoaluminate cement clinker minerals are 3CaO, 3Al2O3, CaSO4 and C2S. Besides the characteristics of early strength and fast hardening, they have micro expansion and sulphate resistance corrosion. The strength of 4 h is 10-25 MPa, and the strength of 1 D is 30-60 MPa. Clinker emergency factors fluoaluminate fast setting and hardening cement is: 11CaO – 7Al2O3 – CaF2, B – C2 s or C3S, which has the properties of fast setting and hardening, condensation quickly, only a few minutes before the initial setting, the initial setting and final setting isolation is very short, not higher than usual 0.5 h, 2-3 h compressive strength is up to 20 mpa. These two kinds of cement are commonly used in the road repair project. Because of the landing trend of the strength and performance of the later period, it is limited in the use scope.

(3) high aluminum cement

High alumina cement is a fast hard and early strong cementitious material. Its an emergency raw material is bauxite and limestone, the clinker’s emergency raw material is an aluminum acid calcium, the hydration speed is very fast, the strength of growth is in the early stage, there is not much growth in the later period. The hydration products of the high alumina cement are unstable, and the crystalline transition is easily produced, and the later strength of the cement will fall. The flexural strength of 1d of high alumina cement can reach 3-5 MPa, and the compressive strength is 25-45 MPa.

(4) magnesium phosphate cement concrete

Magnesium phosphate cement concrete is a new type of road repair materials, the basic preparation process of magnesium phosphate cement: at about 1500 ℃ burning MgO powder, grinding to 1260-3500 cm2 /g, NH4, H2 and PO4 powder is mixed, use na2b4o4 – 10h2o setting time can be made of magnesium phosphate cement. Magnesium phosphate cement has abundant setting time, faster hardening rate and higher early strength. It has strong compatibility and good compatibility with old cement concrete joints. It is a promising pavement repair material.

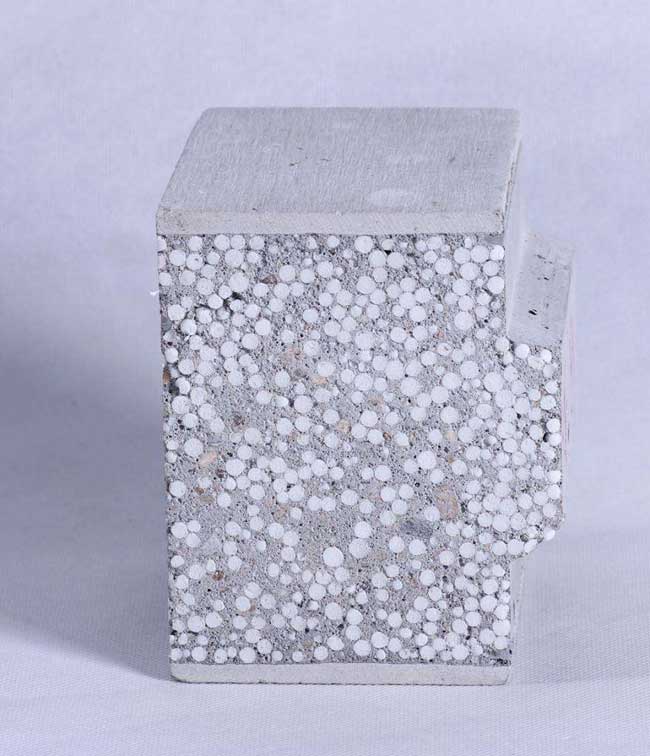

(5) silica fume concrete

Silica fume is a kind of highly active volcano ash admixture, Silica Fume Cement Concrete has high early strength and long-term strength growth is good, on the cement paste and aggregate interface, Ca (OH) 2 is non enrichment, replaced by calcium silicate hydrate gel, so has good interface strength joint. Silica fume concrete has excellent joint performance with old concrete. Silica fume concrete containing 10% to 15% higher content is very suitable for repair of cement concrete pavement.

(6) metakaolin cement concrete

The metakaolin is also a kind of highly active volcanic ash. In the study of silica fume and cement concrete, the introduction of silica fume resulted in the self tightening growth of concrete, while the metakaolin cement concrete had the compensatory shrinkage micro expansion property. The metakaolin cement concrete had better property than silica fume cement concrete. Metakaolin improves the plasticity of cement concrete, strengthens the bond performance, and speeds up the early hydration of cement, gets higher early strength and later strength, and improves the comprehensive performance of cement concrete. The metakaolin concrete has been used for repairing bridge deck and airport runway. It is an ideal material for repair. Its application needs further development and promotion.

(7) polymer modified mortar and concrete

Polymer modified mortar and concrete are another kind of excellent pavement repair materials. The polymers used include natural rubber, synthetic rubber, thermoplastic resin, thermosetting resin, asphalt and paraffin, etc. the emulsion concentration is usually 40% to 60% by weight. Polymer modified cement mortar and concrete repair material of unsaturated polyester resin mortar and concrete, SBR latex modified polyacrylate resin mortar and concrete, mortar and concrete, natural rubber latex modified mortar and concrete, polyvinyl acetate modified mortar and concrete etc. Polymer modified mortar and concrete has high adhesion, anti strike performance, and abrasion resistance of concrete innovation, the waterproof performance is good, excellent performance, but because of the expensive polymer, have some toxicity, high temperature resistant performance is poor, so it is limited in the use.