Condensed silica fume is highly reactive material that is used in relatively small amounts to enhance the properties of concrete. It is a by-product of producing certain metals in electric furnaces.

The main component of the condensed silica fume is amorphous silica, and the furnace gas is also entrapped with impurities, such as free C, Fe2O3, CaO, K2O, Na2O and so on. The color of silica fume change from white to gray, gray, dark gray with C, Fe2O3 content.

Condensed silica fume is frequently referred to by other names, such as: condensed silica fume, Microsilica, Silica fume. There are several materials that are physically and chemically quite similar to condensed silica fume. Some of these materials may perform well in concrete; however, their cost usually prohibits such use:

Precipitated silica

Fumed silica

Gel silica

Colloidal silica

Silica flour and silica dust

Caution: these materials are a crystalline form of silica that will not perform like condensed silica fume in concrete.

Testing Standards of Silica fume:

GB/T 18736-2002

BS EN ISO 12677:2011

BS EN 13263-1:2005 +A1: 2009

EN 13263-1:2005 +A1: 2009 (E)

ASTM C 1240

The characteristics of Condensed silica fume are mainly manifested in two aspects: volcanic ash activity and microgranularity. Therefore, the microsilica is used as filling material and modified admixture.

– used for the high performance concrete, improve the strength of concrete, improve performance, prolong the service life of concrete;

– used for the refractory material, to enhance liquidity, reduce water consumption, improve product strength and durability;

– For the dry powder mortar, grouting material, improve the early strength;

– For the wear-resistant floor, increase fluidity, improve abrasion resistance;

– used for the filling for paint, coating, resin, rubber and other polymeric materials

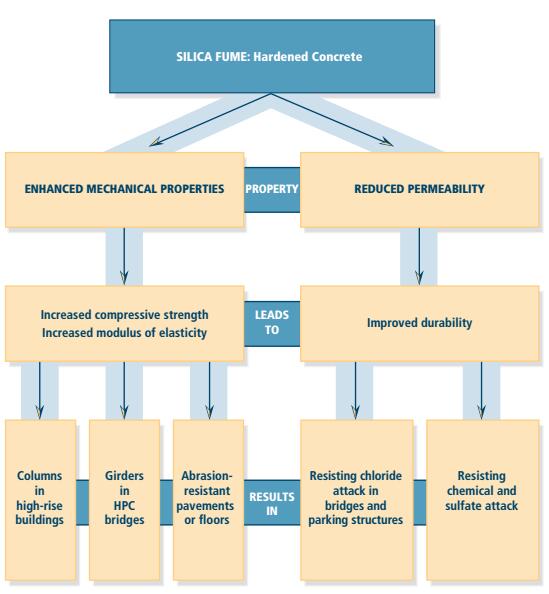

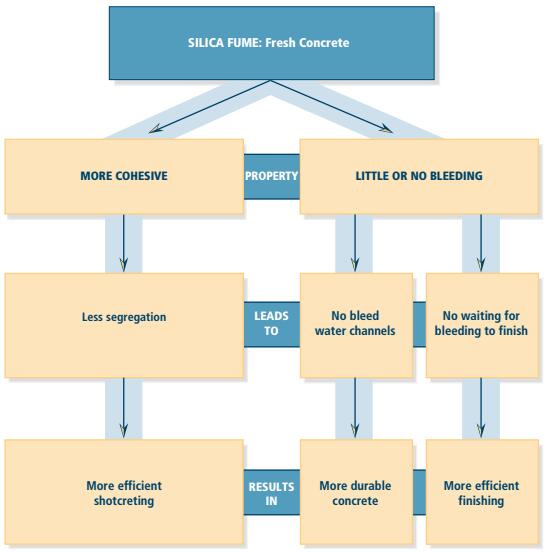

Condensed silica fume is used in concrete because it significantly improves the properties of fresh and hardened concrete. Condensed silica fume is a property enhancing material:

– it is not replacement material for portland cement.

– To increase the span of a bridge.

– To increase the span of a bridge.

– To reduce the section height for a given span.

| Product item | Condensed silica fume / silica fume |

| Main Material | SiO2 |

| State | Non-amorphous Ultrafine (non-crystalline)powder |

| Color | Grey to medium grey powder, white and black powder |

| Buck density-Densified | 630-680kg/m3 |

| Bulk density-Undensified | 320-360 kg/m3 |

| MOQ | Any Quantity meet your requirements |

| Sample Time | 3-5 days if you want to test |

| Certification available | Yes-SGS, ASTM-C1240 etc |

| Packing Detail | 10kg soluble paper bags x 84 on the pallets; 20kg soluble paper bags x 42 on the pallets. |

| 950kg plastic woven bags x 2 on the pallets(with or without bottom output ); 1000kg plastic woven bags x 2 on the pallets(with or without bottom output ); 500kg plastic woven bags x 2 on the pallets (with or without bottom output ) | |

| Production Capacity | 4000 Ton/Tons per month |

Henan Superior Abrasives I/E Co., Ltd is one of the largest Silica Fume Suppliers in China, our products are 85% densified/undensified silica fume, 92% densified/undensified silica fume, 94% densified/undensified silica fume, 96% densified/undensified silica fume.

If you want to know more technology, please coontact us by E-mail sales@superior-abrasives.com or directly leave your message on the following form, thank you.