Silica fume has been recognized as a material of pozzolanic admixture that is highly effective in enhancing mechanical properties. By using silica fume along with super plasticizers, it is relatively easier to obtain compressive strengths of order of 100–150MPa in laboratory. Addition of silica fume to concrete improves its durability through reduction in the permeability and pore structure, leading to a reduction in the diffusion of harmful ions, reducing calcium hydroxide content, which results in a higher resistance to sulfate attack. Improvement in durability will also improve the ability of silica fume concrete in protecting the embedded steel from corrosion.

With regard to handling and availability, SF is available in dry and wet conditions. The former can be provided as produced, with or without dry admixtures,and it can be stored in silos and hoppers. Silica fume slurry with low or high dosages of chemical admixtures is available. Slurried products are stored in tanks. Adding silica fume to concrete significantly reduces bleeding, blocking the pores of fresh concrete and high early compressive strength while not significantly increasing the unit weight of concrete.

Construction chemical microsilica in concrete function:

1, micro silica fume makes high strength concrete (above C70), which can significantly improve the strength and pumping performance of concrete.

2, manufacturing high permeability (more than P30), the structure self waterproofing concrete, used for the subway, tunnel, high-rise building basement;

3, the size distribution of microsilica fume is reasonable, strong dense, hardness and wear resistance. It can greatly improve the tensile strength, compressive strength, impact strength and wear resistance of the cured products, and the abrasion resistance can be increased by 0.5 to 2.5 times.

4, the silica fume can increase the thermal conductivity, change the adhesive viscosity and increase the flame retardancy.

5, it can reduce the exothermic peak temperature of curing reaction of epoxy resin, reduce the linear expansion coefficient and shrinkage rate of solidified products, thereby eliminating internal stress and preventing cracking.

6. Due to the fine grain size and reasonable distribution of the microsilica fume, it can effectively reduce and eliminate precipitation and stratification.

7. The microsilica is pure, the impurity content is low, the physicochemical property is stable, which makes the curing material have good insulation property and anti arc property.

8, manufacturing marine and chemical concrete, because of its high density performance, effectively prevent the penetration and erosion of sulfate and chloride ions to concrete, and avoid corrosion of concrete bars, thereby prolonging the life of concrete.

9, the chemical composition of micro silica fume powder is silica (SiO2), which belongs to inert material. It has no chemical reaction with most acids and alkaloids. Microsilica is evenly distributed and covered on the surface of objects. It has strong corrosion resistance and cavitation resistance increased by 3 to 16 times.

10, the bulk density of silica fume is small: one is between 0.2-0.8 and one is between 1.0-2.2. As polymer filling material, it can reduce the cost by reducing the amount of loading and saving the amount of polymer.

11, micro silica fume frost resistance: after 300 to 500 cycles of rapid freezing and thawing, the relative elastic modulus of microsilica fume is increased by 10 to 20%, while through 25 to 50 cycles, the relative elastic modulus of ordinary concrete is low to 30 – 73%. Therefore, the frost resistance of concrete can be improved.

12, the early strength of silica fume: micro silicon fume powder concrete makes the induction period shorten and has the characteristics of early strength.

13, microsilica in water conservancy, highway and bridge engineering project, concrete not only need the basic index, has very stringent requirements on its wear resistance and erosion resistance, so mixing micro silica fume is very necessary;

14, the strong activity of microsilica powder, has the water reducing performance, suitable for early strength, high strength concrete admixtures; tunnel, subway, process of the large structure in the foundation pit construction for the high strength of sprayed concrete admixtures; underwater construction project (such as: Bridge pier, dam, drilling platform, etc.) as the concrete admixture;

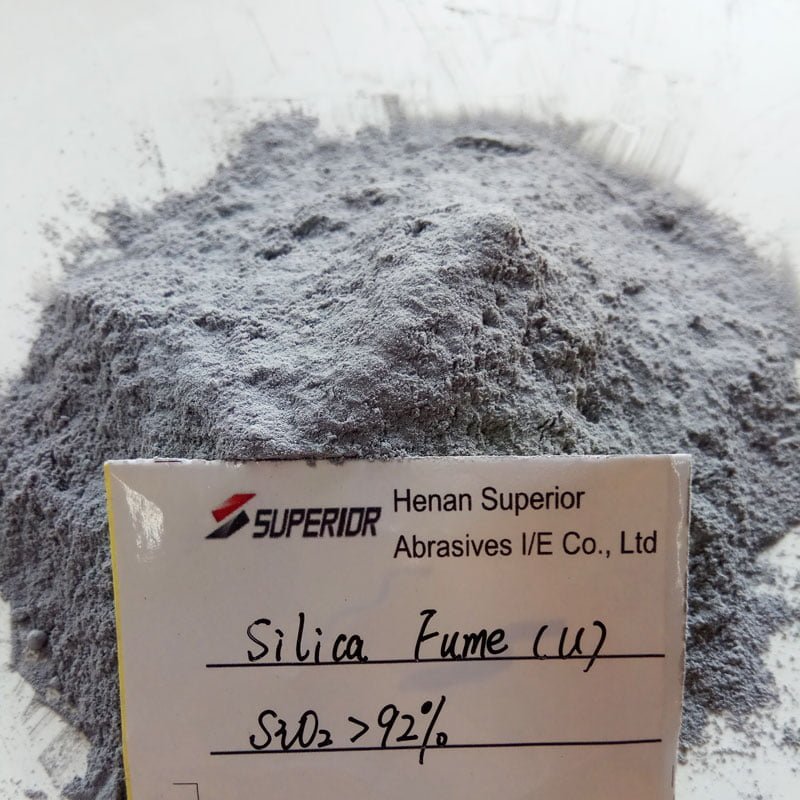

Low price advanced construction chemical microsilica in concrete:

Because the micro silicon powder is a by-product, it used to be waste, and it is now used in a comprehensive way, widely used in construction, building, oil well, refractory and other application. So the price of silica fume is low, but different specification silica fume has different price, generally undensified microsilica price is lower than densified silica fume. In Henan Superior Abrasives factory, we can produce 85 grade silica fume, 92 grade silica fume, 94 grade silica fume, 96 grade silica fume.

Our silica fume Specifications are: https://microsilica-fume.com/shop

chemical microsilica in concrete price is US $ 150-500 per 1 tons.

If you want to know the detailed chemical microsilica price, please contact us directly by E-mail sales@superior-abrasives.com we will reply you in 24 hours, thank you.