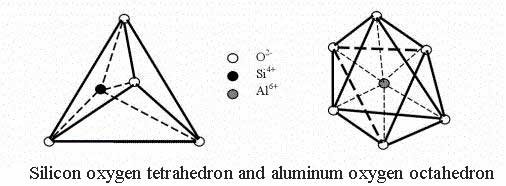

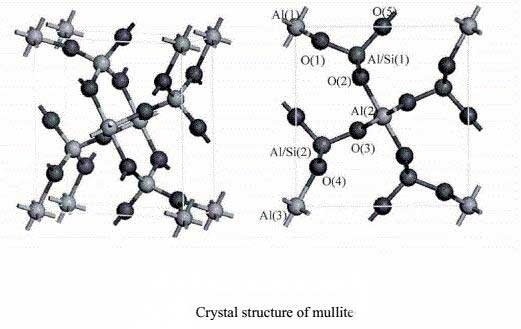

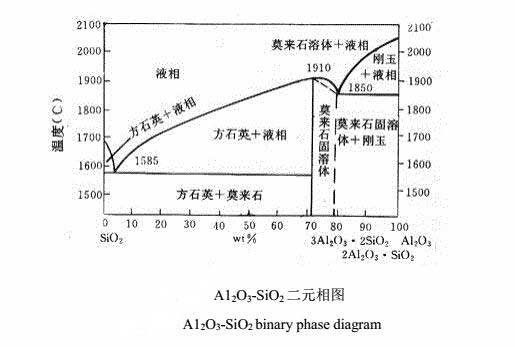

Mullite(3Al2O3.2SiO2) is a ceramic material with high temperature stability, high temperature creep resistance, high temperature mechanical properties and excellent chemical stability, low temperature expansion and good electrical insulation. As high-temperature refractory material and composite materials, mullite is widely used in such fields as national defense, industry and civil use.

The properties of Mullite:

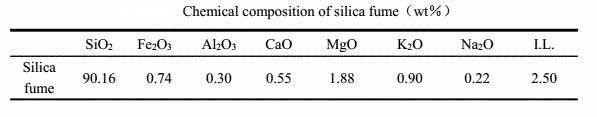

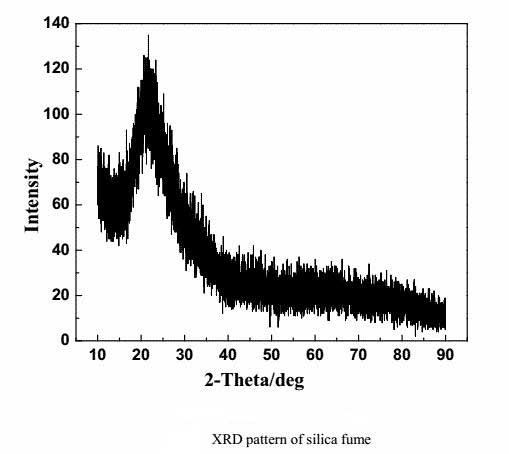

Silica fume (SF) is a by-product of the smelting process in the silicon and ferrosilicon industry. Because of its extreme fineness, high compressive strength, high tensile, high flexural strength, high modulus of elasticity, higher bond strength, very low permeability to chloride and water intrusion, increased abrasion resistance on decks, floors, overlays and marine structures, superior resistance to chemical attack from chlorides, acids, nitrates and sulfates and life-cycle cost efficiencies, silica fume is a promising material to use in ceramics application as a source of silica. Also, the high surface area and amorphous nature of silica fume make it highly reactive.

Microsilica has a high content of SiO2, generally 60%-98%, and contains other minor impurity components such as free C, Fe2O3, Al2O3, K2O, Na2O. The variation of the chemical composition of the micro-silica fume mainly depends on the type of the ore furnace, the design of the smelting process and the chemical composition of the smelting raw materials.

Microsilica for Alumina–Mullite Ceramic Composites

1. Compared with amorphous SiO2 as silicon source, micro-silica fume is more conducive to the occurrence of mullite chemical reaction with industrial alumina powder;

2. Using microsilica and industrial alumina as raw materials, mullite powder was synthesized by the solid phase reaction. The molar ratio of Al2O3/SiO2 was 3:2.5, the calcination temperature was 1450 degree, and the content of mullite in the prepared powder was the highest at 4h.

3. The average particle size of mullite powder decreases with the milling time, and the particle size distribution changes from the initial unimodal distribution to bimodal distribution. The average particle size of the final powder is 0.58um. With large specific surface area, the value is 9.26 m2/g.