As a lightweight cement based foamed material, the addition of silica fume in foam concrete has the following effect:

1. It can improve the performance of compression, bending, seepage, anticorrosion, anti-impact and wear resistance.

2, has water retention and prevent the segregation, secrete water, greatly reduce the concrete pumping resistance effect.

3, prolong the service life of concrete. In particular, the durability of concrete can improve doubled or even several doubled in the harsh environment, such as chloride and salt erosion, sulfate erosion, high humidity and so on.

4, has about 5 times the effect of cement, it can reduce cost in the application of ordinary concrete and low cement castable.

5, it has strong pozzolanic effect. When mixing concrete, it can react with cement hydration product Ca(OH)2 to form second hydration products, form cementitious product, fill cement paste structure, improve slurry microstructure, and improve mechanical properties and durability of hardened body.

6. Silica fume is an amorphous spherical particle, which can improve the rheological properties of foam concrete.

7, the average particle size of silica fume is relatively small, which has good filling effect, and can be filled between cement particles to improve the strength and durability of concrete.

Silica fume amount and foam concrete performance:

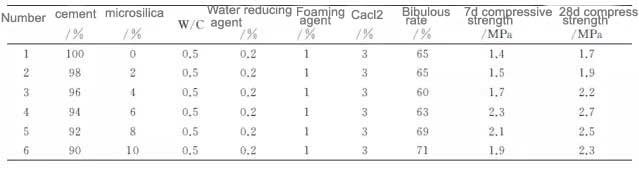

In the foamed concrete, 2%, 4%, 6%, 8% and 10% silica fume (silica fume accounted for the total amount of cement and silica fume) was added to the foamed concrete, and the water absorption and compressive strength of the concrete were determined:

With increasing content of silica fume, water absorbent ratio of foam concrete increases, the 7d compressive strength change, when silica fume quantity is 6%, the compressive strength reached 2.3 MPa, more than 0.9 MPa of samples without silica fume, 28d compressive strength is 2.7 MPa, water absorption rate decreased by 2%, the overall effect is obvious.

Major active SiO2 (Silicon dioxide) in silica fume react calcium hydroxide with cement hydration, which increases the volume of CSH gel, reduces porosity, improves pore structure and improves strength of cement paste. But the specific surface area of silica fume is larger, which makes it show high water demand.