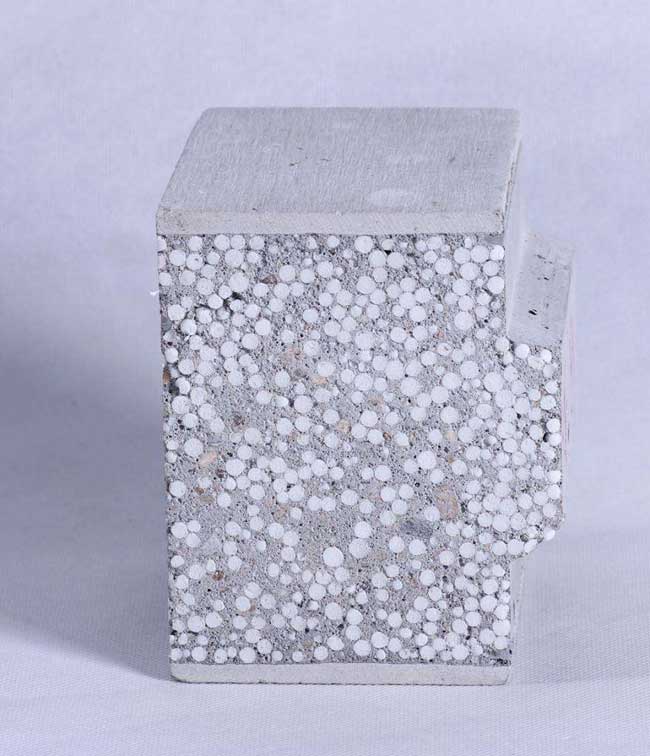

Lightweight partition board is mainly composed of cement, fly ash, microsilica fume, fiber and other main materials, and is made of lightweight and porous concrete board by physical foaming and cutting technology.

Light partition board has the advantages of light weight, high strength, multiple protection, thermal insulation, sound insulation, fireproofing, and rapid construction, reduce the wall cost; the weight is only 1/8 of solid brick, strength can up to C30, the heat conduction rate is only 1/3 of solid brick, acoustic transmission rate is only 1/4, automatic adjustment indoor air humidity, save industrial waste occupied land, prevent industrial waste on air and water pollution, saving fifteen to twenty percent cost, the wall construction efficiency is improved three to five times.

Foamed foam concrete, as one kind of lightweight material for cement based foaming material, has the following effect by adding microsilica:

1. It can improve the performance of compression, bending, seepage, anticorrosion, impact and wear resistance.

2, prolong the service life of cement products. Especially in the bad environment such as chloride and salt erosion, sulfate erosion, high humidity, and so on, the durability of products can be increased double or even several times.

3, with about 5 times of cement effect, it can reduce cost in the application of ordinary concrete and low cement castable.

4, it has strong pozzolanic effect. When mixing concrete, it can react with cement hydration product Ca (OH) 2 to react hydration, form cementitious product, fill cement paste structure, improve slurry microstructure, and improve mechanical properties and durability of hardened body.

5. The micro silica fume is an amorphous spherical particle, which can improve the rheological properties of the foam concrete.6, the average particle size of micro silica fume powder is relatively small, which has good filling effect, and can be filled between cement particles, improve the strength and durability of concrete.