Silica fume concrete basic physical and mechanical properties:

1. The compatibility of new mixed concrete

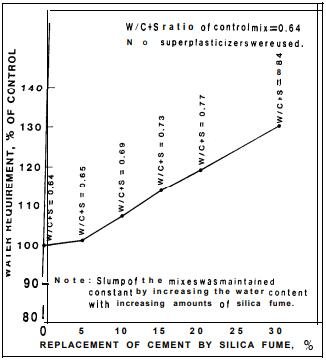

The surface area of the silica fume is very large, and the wetting of the particles surface requires a lot of water.

A lot of free water of fresh concrete is restrained by silica particles. It is difficult for concrete to overflow with excess water. On the other hand, silica fume powder particles block the pores of fresh concrete. Therefore, mixing silica fume into concrete can improve the cohesiveness and water holding capacity of concrete, but the fluidity decreases greatly, and the decrease of fluidity generally increases with the increase of silica fume consumption.

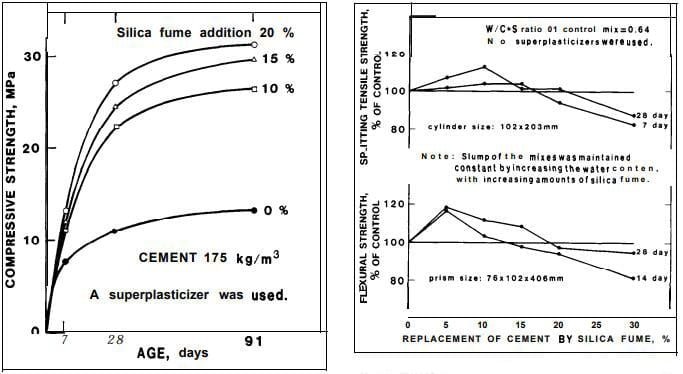

The strength development of silica fume concrete is slightly slower. The effect of silica fume on the strength development of concrete is mainly from 3 – 28d, but the absolute strength of concrete will be greatly improved by appropriate amount of silica fume. when the silica powder content is less than 20%, the strength of concrete increases with the increase of silica fume content, When the dosage is more than 20%, the contribution rate of silica fume to the strength of concrete decreases significantly, or even no longer increases with the silica fume addition increase.

3. Dry shrinkage of silica fume concrete

Adding silica fume in concrete, as the micro filler effect of microsilica, silica fume its water absorption is large, the amount of bleeding of fresh concrete is greatly reduced, and the silica fume concrete early hydration reaction accelerated, the early strength increased, the modulus of elasticity increased, and the creep and stress relaxation decreased. Therefore, the plastic cracking of silica fume concrete (usually in the concrete pouring plaster to the concrete before the final setting) and early (28d) than that of ordinary concrete shrinkage crack opportunities greatly increased, and increases with the increase of silica content, and later (after 60d) for concrete small porosity, compact structure, water transfer difficulties, volume change trend is relatively flat, and its shrinkage is similar to that of ordinary concrete or reduced.

4. Thermal properties of microsilica powder concrete

4. Thermal properties of microsilica powder concrete

Adding silica fume in concrete, hydration speed and temperature increased faster usually before 3D, heat peak appeared in advance, but eventually the concrete hydration heat of concrete decreased, the adiabatic temperature rise decreased, especially more significant in low water cement. This is very beneficial to reduce crack caused by mass concrete internal temperature rise.

Durability of silica fume concrete

The durability of concrete includes impermeability, frost resistance, abrasion resistance, and chemical resistance, corrosion resistance, inhibition of alkali aggregate reaction ability and so on.

Silica fume concrete application:

1. hydraulic resistance and abrasion resistant concrete;

2.Marine concrete;

3. high-strength concrete;

4. highway concrete;

5. shotcrete;

Henan Superior Abrasvies Silica fume Concrete Products: http://www.silicafumesupplier.com/category/products/concrete