Mechanism of action: when the silica fume in concrete, silica fume and water contact, some small particles rapid decomposition, in the solution Si02 rich and Ca poor gel forming adhesion layer on silica particles surface, after a certain period of time, Si02 rich and Ca poor gel layer begins to dissolve and hydration of cement produce Ca (OH): reaction generation C – S – H gel.

Benefits of silica fume in concrete:

1. longer service life

Silica fume is a highly reactive pozzolan and gives concrete a denser microstructure, lower permeability & higher electrical resistivity leading to improved durability.

The durability of a reinforced concrete structure can be defined as the capability of the structure to maintain its original functional and structural characteristics during the expected service life in the exposure conditions it was intended for.

Combined with correct design and workmanship, microsilica in concrete offers characteristics that will ensure long term durability and service life.

2. corrosion resistance

Silica fume adding into concrete helps to increase time to initiation of corrosion – by reducing the permeability of concrete, microsilica significantly reduces the rate of penetration of chloride ions into the concrete.

In addition to protection provided by reduced permeabilty, concrete with silica fume has higher electrical resistivity. Increased electrical resistivity helps reduce the rate of corrosion. Increased electrical resistivity of silica fume in concrete is due to the reduced alkali ion concentration in the pore solution, and a more discontinuous capillary pore structure.

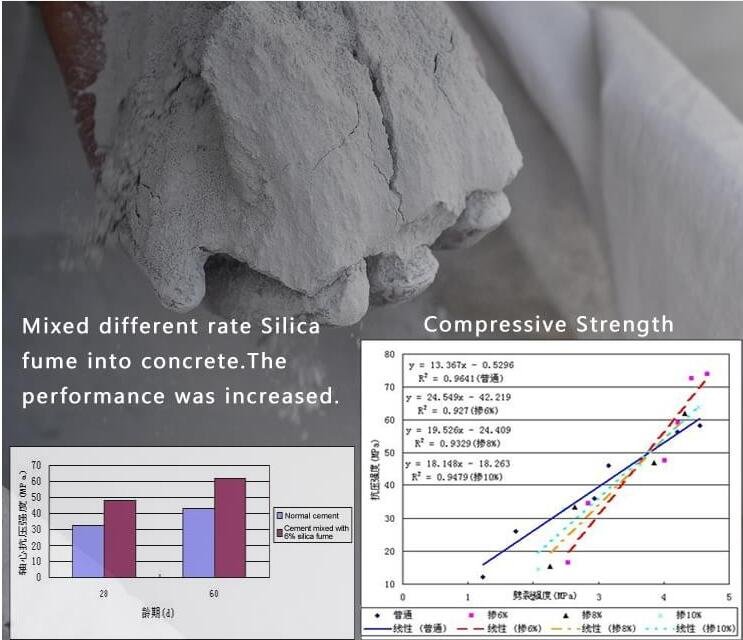

3. higher strength

Silica fume is used to make the high strength concrete that is often essential in major projects, such as record breaking tall buildings.

These engineering applications requiring high strength concrete (>80 MPa) use microsilica as a cost effective means to increase compressive strength. Ultra-high strength concrete (UHSC), typically defined as >150MPa can be achieved using higher dosages of silica fume. Increased strength results from microsilica’s particle packing & pozzolanic reaction. In microsilica concrete, the thickness of the transition zone (interface) between the cementitious paste and aggregate is reduced and the CH crystals are smaller and more randomly oriented, resulting in decreased porosity & increased interface bonding strength.

4. particle packing & mix design

Silica fume improves the particle packing of concrete and mortar mixtures.

5. preventing ASR & sulfate attack of concrete

Silica fume is used to help give concrete integral protection from damage by chemicals, including alkali-silica reaction (ASR) and sulfate attack.

Chemical attack on concrete takes place either by leaching of calcium hydroxide or by ingress of harmful substances, such as sulfates or nitrates. Since microsilica reduces the amount of soluble calcium hydroxide, leaching is reduced, and less is available for the harmful expansive reactions caused by sulfates and nitrates.

The addition of microsilica reduces the permeability of concrete. This retards the leaching and ingress of materials from, or to, the interior of the concrete. Consequently, high performance concrete designed with silica fume can possess superior resistance to chemical attack.

6. Improving rheology of concrete, mortars & grouts

6. Improving rheology of concrete, mortars & grouts

Silica fume plays an important role in improving the rheology of concrete, mortar and grout mixtures.

Microsilica helps prevent both bleeding and segregation. This is due to the strong internal forces caused by the large surface of the microsilica particles, and improved particle packing in the mixture.

A small dose of micro silica fume helps improve pumpability of concrete and makes self-compacting concrete (SCC) more robust.

7. Reducing sprayed concrete rebound and wastage

Silica fume is extensively used in sprayed concrete applications. Benefits are so many, both in the dry and wet processes and include:

– Reduced rebound;

– Increased cohesiveness and stickiness;

– Less dust generation;

– Increased layer thickness;

– Reduced need for accelerator;

– Improved wash-out resistance;

– Improved bond to substrate and reinforcement;

– Improved properties of hardened concrete, including strength and durability;

Other uses of micro silica fume:

1. cement industry: after adding micro silica fume to cement, the performance is improved, the quality and the label are greatly improved.

2. rubber industry: after adding a certain amount of silica fume, the rubber industry has greatly improved its extension, tear resistance and aging resistance. The rubber has good dielectric properties and low water absorption capacity.

3. as an anti caking agent: instead of mica or diatomite as the raw material to prevent the agglomeration of fertilizer particles;

4. as pellet binder, micro silica has large surface area, strong adsorption, adhesive for pellets in foreign countries has significant effect;

5. water glass industry: instead of quartz ore, the production of water glass with 4 modulus;

6. as cementing in oil fields, many oil fields have used silica fume and have achieved good use effect.

7. in insulation materials, waterproof materials, paint, coating, printing industry and other applications.

Silica fumes in concrete factory:

The famous silica fume in concrete factories are many, you can search directly on search engineer, or directly contact us by E-mail sales@superior-abrasives.com our salemen will reply you in 24 hours, thank you.