The application research and recycling of micro silica fume in China started relatively late, and most ferrosilicon production enterprises did not pay enough attention to recover silica fume. Although some large enterprises recovered micro silica powder, they did not find its value, and most of the recovered micro silica silicon dioxide content did not meet the standard, which is still an extensive industrial by-product.

In recent years, due to the attention paid by the state to environmental protection, the management of polluting enterprises has been gradually strengthened, especially the increase in domestic demand for high-strength concrete, many ferroalloy production enterprises have equipped with dust collection equipment and developed and introduced densified technology. China’s silica fume products have developed rapidly, and the gap between China and foreign countries in this field is narrowing. High-strength concrete, silica fume shotcrete, composite density-enhancing agent, silica fume mortar, low-cement castables, etc. have been applied in many projects, with remarkable technical and economic effects.

What is silica fume:https://microsilica-fume.com/what-is-silica-fume.html

The data shows that most industrial silicon production can recover 1 ton silica fume per 3 tons industrial silicon. In 2020, China’s industrial silicon output reach 2.1 million tons, and the potential resources of silica fume powder will reach 700000 tons. However, compared with the relatively mature silicon fume powder market abroad, the research time of silica fume in China is still short, and microsilica is still an extensive industrial by-product in China. In addition, as many manufacturers do not have dust removal and recovery devices or do not pay enough attention to the recovery of silica fume, the recovery in China is relatively low, far from meeting the market demand.

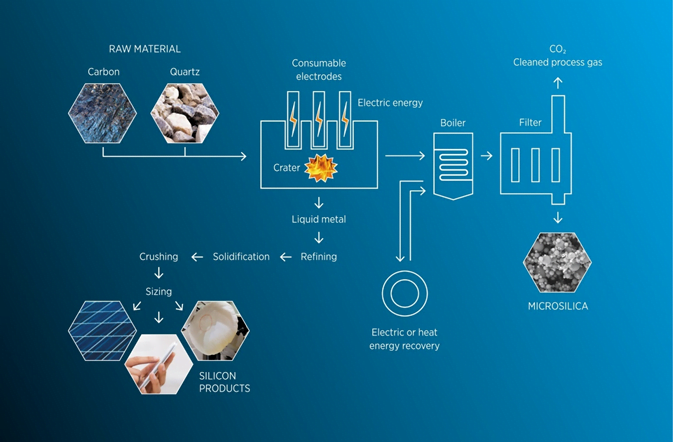

Microsilica fume Production process:

Price status of silica fume:

At present, the market price of silica fume is 1800~3800 RMB per ton. According to the different SiO2 content and use, the price of microsilica fume in the market is also different. Generally, the higher the content of SiO2 and the lower the content of impurities, the higher the price if the factors such as particle size and loss on ignition are not considered. With the increase of market demand, the price tends to rise.

More information about silica fume price: https://microsilica-fume.com/silica-fume-price-per-ton.html

Since 2020, the overall supply of silica fume market has been tight, and the price has increased a lot compared with last year:

1. The supply of microsilica powder (silica fume) with high content and high fluidity is relatively small, which is concentrated in individual silica fume manufacturers, with high price and tight supply.

2. The metal silicon market is weak, resulting in unstable factory production and unstable quality.

3. As a whole industry, the quality of silica fume products varies greatly. At present, the proportion of silica fume powder that meets specific requirements, such as national standards of more than 85% and less than 90% in the market is very low.

4. Due to the high testing cost and the instability of the product itself, the microsilica manufacturer is not clear about its own products.

Foreign silica fume market demand

At present, the demand for silica fume in the international market is increasing year by year. The total output in major foreign countries such as the United States, Russia, Japan and Norway is more than 640000 tons/year, which still cannot meet the market demand. As China’s ferrosilicon and metallic silicon are in a prominent position in the international production (accounting for about 2/3 of the world’s production in 2006), the accompanying micro-silica powder has attracted the attention of foreign end customers, such as the Norwegian Elken Company, which has moved its research and development center to China, with an annual sales of 250000 tons silica fume and a high profit. According to the relevant information, the foreign market of silica fume is huge, and high-quality silica fume is widely used, but the output of high-quality silica fume is very small.

Domestic silica fume market demand

At present, the demand for silica fume in high-rise buildings, railways, bridges and hydraulic buildings is increasing day by day, and the market potential is huge. Concrete is the basic material of the construction industry. The addition of silica fume makes it possible to make high-strength and high-performance concrete. Although high-performance concrete does not mean adding microsilica alone, other fillers such as fly ash and blast furnace slag can improve the performance of concrete, but the addition of silica fume is better in improving the comprehensive performance of concrete. The addition of silica fume will significantly reduce the amount of cement added.

China is the largest consumer of refractories in the world. The application technology of silica fume in refractories is relatively mature, and from the perspective of the development trend of refractories in China, the total demand for refractories is still large, and will continue to maintain a rapid growth trend. It can be used for high-grade cement refractory castables and prefabricated parts, large iron trench and ladle materials, breathable bricks, coating and repairing materials, self-flow refractory castables and dry and wet spraying construction applications, oxide-bonded silicon carbide products (ceramic kiln furniture, flame barrier, etc.), high-temperature calcium silicate lightweight thermal insulation materials, corundum-mullite push plates for electric porcelain kilns, high-temperature wear-resistant materials and products, corundum and ceramic products, Theron bonded products, etc, The application of silica fume in refractories has broad market space. In addition, silica fume can also be used in rubber, pesticide, paint, plastics, high-performance ceramics, compound fertilizer and other fields instead of fumed silica.

Market changes of microsilica (silica fume) in China in 2023

-Growing demand: With the continuous development of China’s urbanization and infrastructure construction, the demand for silica fume is growing rapidly.

-Improved production technology: With the continuous improvement of technology, the production technology is also improving, so as to improve product quality and reduce costs.

-Increasing environmental protection requirements: With the increasing awareness of environmental protection, the environmental protection requirements for the production process are also increasing.

-Increased competition: With the continuous development of the market, the silica fume market is also increasing competition, resulting in more fierce competition for market share.