High performance concrete is accompanied by high strength concrete, and high durability also includes high volume stability, high resistance to permeability and high workability.

High Performance Concrete (HPC) containing silica fume has been identified as one of the more important advanced materials necessary in the effort to rebuild the nation’s infrastructure. In addition to increased strength and enhanced durability, HPC produced with silica fume delivers increased toughness, increased resistance to abrasion, corrosion and chemicals, sustainability and life-cycle cost efficiencies.

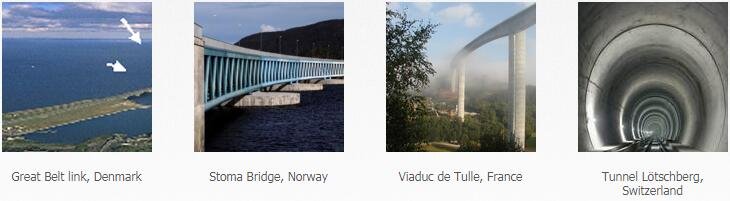

Application:

For highway bridges, parking decks, marine structures and bridge deck overlays which are subjected to constant deterioration caused by rebar corrosion current, abrasion and chemical attack. Silica fume will protect concrete against deicing salts, seawater, road traffic and freeze/thaw cycles. Rebar corrosion activity and concrete deterioration are virtually eliminated, which minimizes maintenance expense.

Silica Fume in High-performance Concrete (HPC) Advantages:

-Very low permeability to chloride and water intrusion

-Extremely high electrical resistivity (20 to 100 times greater than ordinary concrete)

-Increased abrasion and impact resistance on decks, floors, overlays and vertical structures

-Superior resistance to chemical attack from chlorides, acids, nitrates and sulfates