Micro silica Physicochemical Properties:

1, Micro silica appearance: white;Refractoriness > 1600 ℃; Bulk density: 200 to 250 kg / m3.

2, Micro silica fineness: 90% fineness of 0.1μm; average particle size of 0.1 – 0.2μm, specific surface area: 20 – 28 m2 / g. Micro silica fineness and specific surface area is 80 to 100 times of that of cement, 50 to 70 times of fly ash.

3, Micro silica particle morphology and mineralogical structure: Due to the surface tension of the phase change, micro silica fume forms into amorphous phase amorphous spherical particles with smooth surface, or a plurality of ball particles stick together.

Micro silica fume is a high activity pozzolanic material with large surface area. Micro silica in materials will play the role of lubrication with the tiny spherical body.

Silica Fume has a stable pH and a low impurity level and is perfectly adapted to the requirements of refractory castables. Its use improves the flow, mechanical properties (especially hot strength), and durability (via permeability reduction).

Silica fume in refractory castables provides better particle packing. Silica fume use requires less water, while maintaining the same flow characteristics. Silica fume use also promotes low temperature sintering, and the formation of mullite in the matrix of castables. This allows production of castables which have a low permeability to gas, slag and metal penetration. Castables made with silica fume are stronger than non-silica fume castables, especially at high temperatures and higher density. Silica fume use will attain lower porosity and are more volume stable.

Acting as a filler is not the only effect of microsilica in refractory castables. It has been shown in studies of cement pastes with microsilica that a certain fraction of the microsilica reacts with the cement and water to form so-called C-A-S-H (CaO-Al2O3-SiO2-H2O) phases in addition to the C-A-H (CaO-Al2O3-H2O) and A-H (CaO-Al2O3) phases normally found in hydrated cement. The C-A-S-H phases are of zeolitic nature and the amounts of these hydration products are dependent on the quality (purity) of the microsilica.

1. After adding aggregate, add micro silica and cement without delay, then add water and other admixtures.

2. Add coarse aggregate + 75% water + micro silica + 50% fine aggregate, and stirred for 15-30 seconds, then put cement + additive + 50% fine aggregate + 25% water and stirred. Stirring time is 20-25% longer than that of ordinary cement or 50-60. Avoid put the silicon powder to the already mixed concrete.

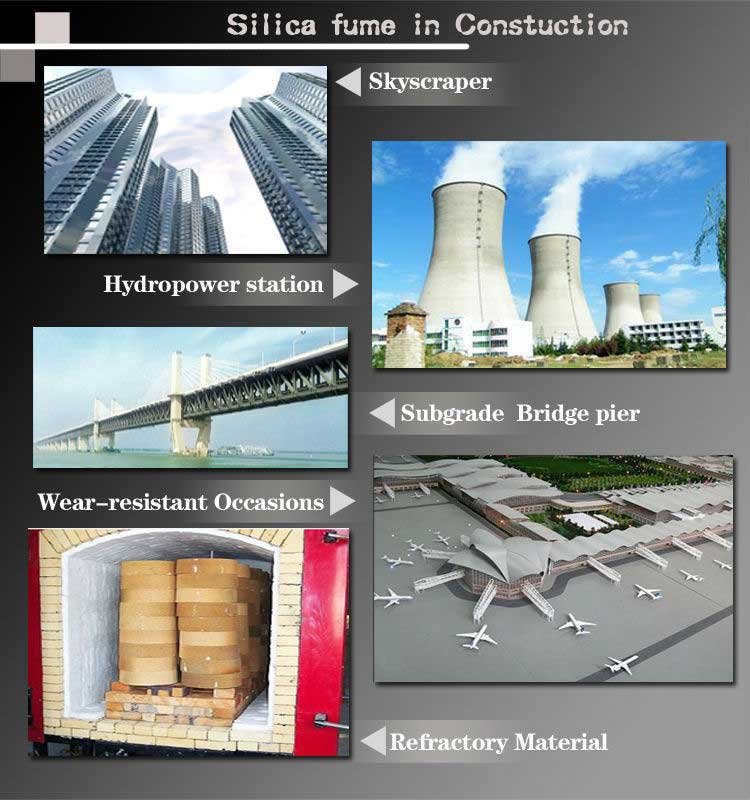

Micro-silica fume is widely used in the refractory industries:

1.Instead of pure aluminum oxide mud as refractory material.

2.As the additive for production of amorphous and shaped refractory products, to improve the strength, and high temperature performance.

3.Other refractory products like cohesive agent, bonding agent, accelerator and additives.