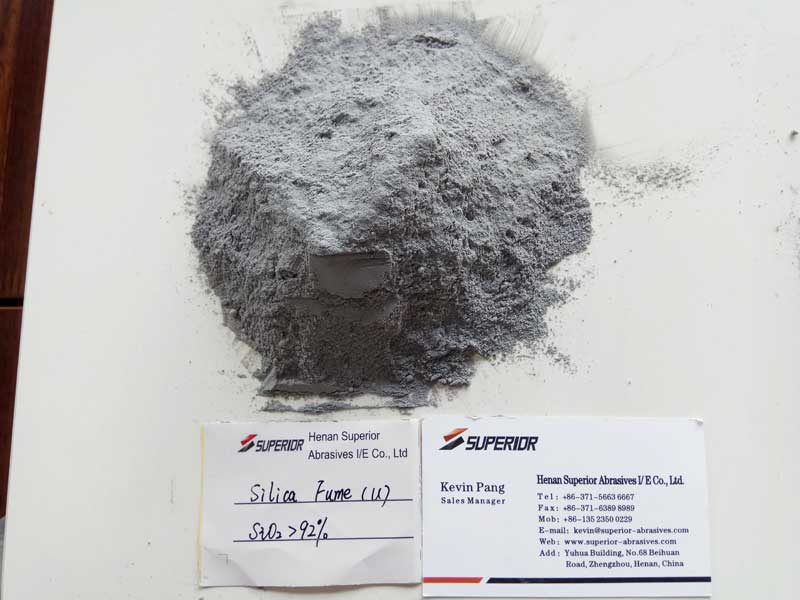

Silica fume Chemical composition:

Silica fume Chemical composition:

L.O.S: 1.69%

SiO2: 95.62%

Al2O3: 0.64%

Fe2O3: 0.05%

CaO: 0.18%

MgO: 0.09%

Microsilica can fill the pores between the cement particles, increase the volume density and decreases the porosity, while micro silica fume has volcano ash reaction, with hydration products generate gels, and with alkaline materials Magnesium Oxide reaction gel. Silica fume can work with cement hydrated gel C-S-H, its strength is higher than that of Ca (OH) 2 crystal.

In cement based concrete, mortar and refractory castables, a proper amount of silica fume is added to the concrete, which can play the following role:

1. It can improve the performance of compression, bending resistance, seepage resistance, anticorrosion, anti-impact and wear resistance.

2, has water retention and prevent the segregation, secrete water, greatly reduce the concrete pumping resistance effect.

3, prolong the service life of concrete. In particular, the durability of concrete can be doubled or even doubled in the harsh environment, such as chloride and salt erosion, sulfate erosion, high humidity and so on.

4, the ground ash of the sprayed concrete and castable is greatly reduced and the thickness of the single injection layer is improved.

5. It is a necessary component of high strength concrete. It has been applied to the engineering of C150 concrete.

6. has the effect of about 5 times cement, it can reduce the cost and improve the durability of the ordinary concrete and the low cement castable.

7, effectively prevent the occurrence of concrete alkali aggregate reaction.

8. Improve the compactness of the castable refractory. With Al2O3 coexist, easy to form mullite phase, the high temperature strength, heat shock resistance enhancement.