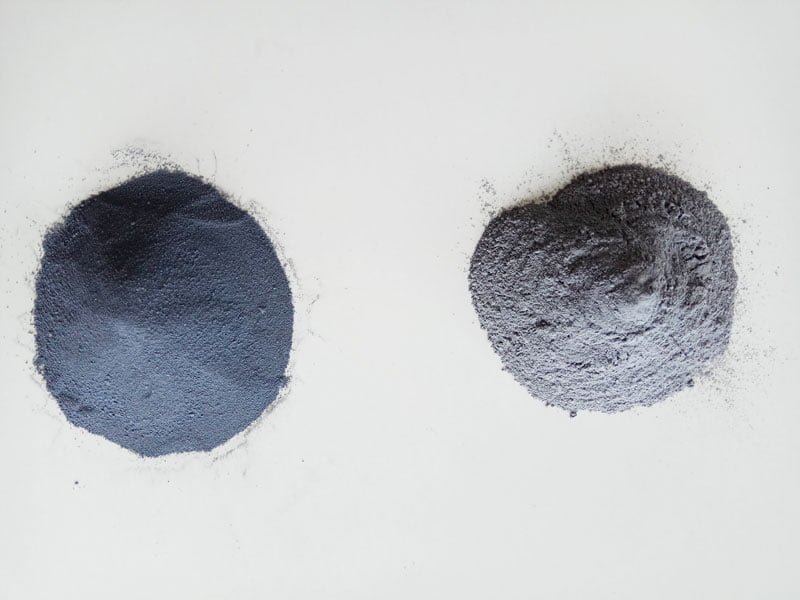

Microsilica can be filled in the pores of cement particles, and with hydration products produce gel, with alkaline material Magnesium Oxide produce gel. In cement based concrete, mortar and refractory castables, a proper amount of silica fume is added to the cement, and the effect of water reducing and strengthening can be played. In fact, this is the main feature of the micro silica fume, because it not only has high volcanic ash activity, but also its specific surface area is larger. Because the fineness of the microsilicon powder is less than 80%, the average particle size is from 0.1 to 0.3um, and the specific surface area is 20 – 28m2/g. The fineness and specific surface area are about 80-100 times of the cement and 50-70 times of the fly ash.

1. fineness indicates the fineness degree of powdery raw materials. It is often expressed as standard sieve percentage or specific surface area. It can also be expressed by percentage of particle size or average value of unit weight material. There is no strict distinction between fineness and particle.

2. The specific surface area is the surface area of the raw material per unit weight, and the unit is m2/g. The specific surface area is divided into two kinds of external specific surface area and internal specific surface area. The ideal non-porous materials have only outer surface area, but there are internal specific surface areas in addition to the external surface area of the raw materials with pores. There are many methods to determine the specific surface area, such as gas adsorption, organic molecular adsorption and air permeability.

3. The calculation method of specific surface area of microsilica:

The particle size of silica fume samples can be conveniently measured by transmission electron microscopy. The length of the scale is 100nm, and the particle size of micro silica fume samples is between 10-100nm and the average particle size is 30-40nm. For example: 40nm.

(1), the volume of single grain micro silica V=4/3×π×(40×10-9)3=2.68×10-22m3

(2). The surface area of single grain micro silicon powder is S=4π×(40×10-9)2=2.01×10-14m2

(3), micro silica proportion is 2600kg/m3, each 1 kg micro silica particle number: 1/2600÷2.68×10-22=1.44×1018.

So the surface area of silica fume per 1kg is 1.44×1018×2.01×10-14=29000 m2.

The above value is only as reference, if you want to know the detailed value about silica fume, please contact us by E-mail sales@superior-abrasives.com thank you.