Definition:

Silica Fume: Very fine non-crystalline silica produced in electric arc furnaces as a by product of the production of elemental silicon or alloys containing silicon-ACI 116R-Grey colored powder similar to Portland cement or some fly ash.

Fly Ash: Fly ash is a group of materials that can vary significantly in composition. It is residue left from burning coal, which is collected on an electrostatic precipitator or in a bag house. It mixes with flue gases that result when powdered coal is used to produce electric power.

Fly Ash standards:

Class F is made from burning anthracite and/or bituminous coal.

Class C is produced from lignite or sub bituminous coal. In Canada, there is a further distinction.

When the lime content is 8-20 percent, it is classified Cl, and when it is higher, it is class C.

Silica Fume ( ASTM C1240 ) :

Minimum Silicon Dioxide of 85 %

Maximum Moisture content to 3 %

Maximum loss in ignition to 6 %

The Oversize materials retained on a 45- m ( No.325) sieve to maximum of 10 %.

The maximum variation from average be no more than 5% points .

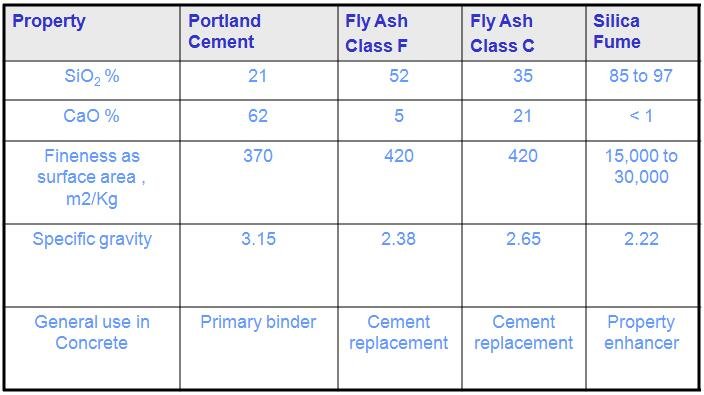

Comparison of chemical and physical Characteristics Fly Ash, Silica Fume and Portland cement:

Silica Fume is typically much more reactive, particularly at early ages , because of its higher silicon dioxide content and because of its very small particle size.

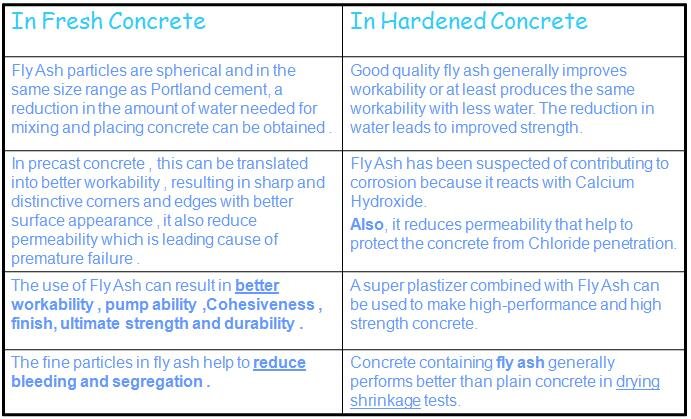

Advantages of Fly Ash :

Disadvantages of Fly Ash:

– Poor-quality fly ash can have a negative effect on concrete (increase permeability ).

– Some concrete will set slowly when fly ash is used. Though this might be perceived as a disadvantage, it can actually be a benefit by reducing thermal stress .

– Freeze-thaw durability may not be acceptable with the use of fly ash in concrete.

– High-carbon fly ash materials tend to use more water and darken the concrete as well.

Reaction of Silica fume in Concrete:

The benefit seen from adding Silica Fume are the result of changes to the microstructure of the concrete.

Physical Contribution of silica fume:

– Adding Silica Fume brings millions and millions of very small particles to concrete mixture.

– Just like fine aggregates fills in the spaces between coarse aggregate particles, Silica Fume fills in the spaces between cement grains.

– This phenomenon is frequently referred to as particle packing or micro-filling.

Even if Silica Fume didn’t react chemically, the micro-filler effect would bring about significant improvement in the nature of the concrete.

Chemical Contribution of silica fume:

– It is a very high amorphous silicon dioxide content because of that silica fume is a very reactive Pozzolanic material in concrete.

– As the Portland Cement in concrete begins to react chemically it releases Calcium hydroxide.

– The Silica Fume reacts with this Calcium hydroxide to form additional binder material called Calcium Silicate hydrate , which is very similar to the Calcium hydrate formed from the Portland cement.

– It is largely this additional binder that gives silica-fume concrete its improved hardened properties.

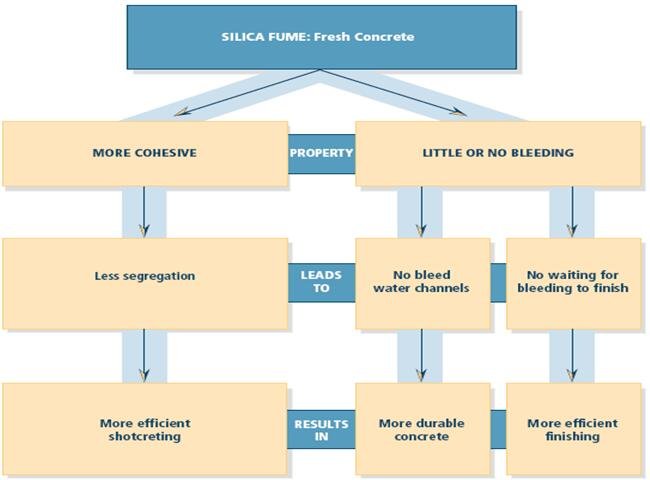

Effect of Silica Fume on fresh concrete and how those effects improve constructability and the final concrete:

Effect of Silica Fume on Hardened Concrete and how those effects are used in concrete applications: