Silica fume is a kind of concrete admixture with extremely small particle size formed in the process of metallurgical industry and industrial silicon production. Silica fume contains a large amount of amorphous silica, and the particle size is very small, and it has strong bonding force, so it is suitable for the concrete industry.

The application methods of silica fume are generally divided into two types: one is to use silica fume as a mixture in cement; the other is to add silica fume to concrete. The mechanism of action of the two application methods is the same, and the enhancement effect is basically same.

The effect of silica fume on workability of concrete

Adding silica fume to concrete can improve the stable performance of concrete, that is, it can reduce the segregation and bleeding of concrete. Due to the large size of sand and stone used in concrete, the mixing water in concrete can flow through the pores between these aggregates, while silica fume can block these pores due to the small particle size and cut off the flow channel of the bleeding process. And the addition of silica fume can increase the contact point between solid and solid, and increase the cohesion inside the concrete. However, when the content of silica fume in the concrete is > 20%, the viscosity of the concrete will increase greatly, which will increase the difficulty of construction; and when the content of silica fume is < 10%, it can ensure that the water consumption and water reduction will not be increased, and keep the concrete with good fluidity. When the slump of concrete is constant, the water consumption of concrete increases proportionally with the content of silica fume. When this happens, an appropriate amount of superplasticizer can be added to reduce the water consumption of concrete. When the content of silica fume in concrete is 10% to 20%, in order to ensure the slump and fluidity of concrete, under the condition that the water-cement ratio remains unchanged, the amount of water reducing agent should be increased to improve the strength and durability of concrete.

The effect of silica fume on the setting time of concrete

Many studies have shown that adding a certain amount of silica fume to concrete has no significant effect on the setting time of concrete. For example, the research by Pistilli M F and others showed that when the dosage of ordinary Portland cement was 237 kg/m3 and the amount of silica fume was 24 kg/m3, the initial setting time and final setting time of concrete were prolonged by 26 min and 29 min respectively, can have a retarding effect.

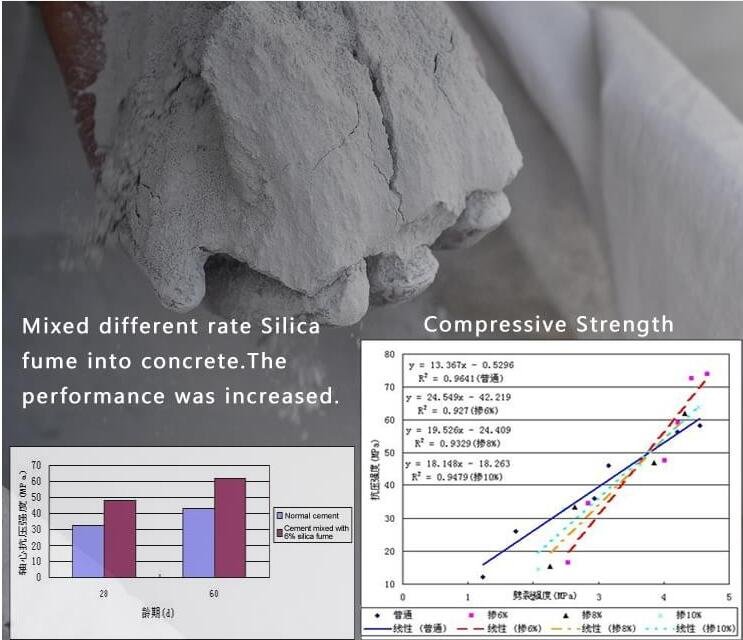

The effect of silica fume on concrete strength

The influence of silica fume on concrete strength mainly reflected in its use in concrete, that is, whether silica fume is applied to concrete in the form of concrete material, or in the way of replacing the amount of cement in concrete. Usually, a certain amount of water-reducing agent is added to the concrete mixed with silica fume, to keep the water-cement ratio of the concrete unchanged. At this time, it is meaningful to analyze the influence of silica fume on the strength of concrete, especially the 5% amount of silica fume is most useful.

Generally, silica fume is applied to concrete, which has no great influence on the strength of concrete from 1 d to 3 d, but has a great influence on the strength of concrete from 3 d to 28 d, which can significantly improve the strength of concrete, and has a great influence on the strength of concrete. 28 d to 90 d intensity has little effect.

The effect of silica fume on the impermeability of concrete

The durability of concrete against erosive water generally depends on the impermeability of concrete. Due to the small particle size of silica fume, the size and number of pores in concrete can be improved. When the content of silica fume in concrete is 10%, the concrete remains basically impermeable at 7 d and 28 d age, which can be effectively reduced pore size in concrete.

The effect of silica fume on the wear resistance of concrete

In general, the wear resistance of concrete is directly related to the strength of concrete. When the density of the concrete is high and the aggregate used in the concrete is hard, the concrete can have high strength and high wear resistance.

The effect of silica fume on chemical corrosion resistance of concrete

After adding silica fume to concrete, it can not only improve its strength and wear resistance, but also improve its acid resistance or sulfate resistance. After adding silica fume to concrete, the content of calcium hydroxide in concrete can be reduced. When the replacement rate of silica fume in concrete reaches 20%, the content of calcium hydroxide generated by hydration reaction in concrete is basically zero; When the replacement rate of silica fume is 25%, calcium hydroxide does not exist when the concrete is 28 d old.

Technical characteristics of silica fume applied to concrete

Silica fume is usually used as an auxiliary cementitious material in concrete, but with the progress of society and the development of the concrete industry, the application of silica fume in concrete also has other technical advantages, such as high strength and high durability, and silica fume is usually used as a substitute for cement cementitious materials in concrete, which can reduce the heat of hydration, etc. From the perspective of improving the strength of concrete with silica fume, after using silica fume to replace a certain amount of cement in concrete, the strength of concrete is increased by 2 to 3 times of the replacement amount. After adding silica fume into concrete, a certain amount of superplasticizer is usually added, especially when the content of silica fume in concrete is > 5%, a certain amount of superplasticizer must be added.

The newly poured silica fume concrete is sensitive to temperature, and shrinkage cracks may appear when the temperature is too low, so it should be strengthened. When the water evaporation rate on the concrete surface is > 1 kg/(m2·h), not only normal maintenance should be ensured, but also appropriate measures should be taken to prevent the water evaporation on the concrete surface. Generally, humidification maintenance, hood maintenance, cooling partition maintenance, spray maintenance after covering maintenance should be adopted.

Silica fume is widely used in concrete. Adding a certain amount of silica fume to concrete can improve the strength, impermeability, wear resistance and chemical corrosion resistance of concrete, especially its role in resistance to chloride ion corrosion is irreplaceable. The main reason is that the particle size of silica fume is small, and it can participate in the hydration reaction of cement, and is distributed into the concrete to generate a hard and strong cementitious substance, which improves the compactness of the concrete, thereby improving the concrete’s durability strength and other properties.