Thermal insulation materials are usually light, loose, porous and low thermal conductivity materials. The thermal conductivity of commonly used thermal insulation materials is less than 623K (350 ℃), and the thermal conductivity should be less than 0.14W / (M. K). Thermal insulation material can slow down heat flow rate produced by conduction, convection, radiation and play the role in preventing high temperature to low temperature, isolating solar radiation and high temperature influence.

There are many kinds of classification methods for thermal insulation materials:

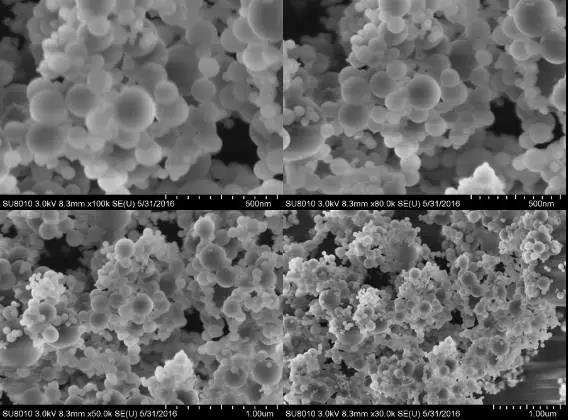

1, according to the different state and structure, can be divided into foam insulation materials (i.e. solid matrix continuous and discontinuous, stomatal), powder insulation materials (i.e. discontinuous and continuous solid matrix pores), fibrous or multi layer insulation materials (i.e. continuous solid matrix and porosity);

2. According to the different forms, it can be divided into plate thermal insulation materials and slurry thermal insulation materials, etc.

3. According to the different material, it can be divided into organic heat insulation material and inorganic thermal insulation material.

Microsilica applied in thermal insulation materials:

The application of micro silica fume as the main raw material to prepare composite silicate insulation material has gradually become the hot spot of silica fume application. The composite silicate thermal insulation coating is one of the most widely used thermal insulation coatings at present. It is a barrier type thermal insulation coating. It is a new type of energy-efficient thermal insulation coating with micro mesh structure. This kind of thermal insulation coating was originally used as the main raw material for the release of sepiolite, with water glass as the main binder. Later in addition to sepiolite, also added a large amount of perlite, vermiculite, cenosphere, fly ash, silica fume, diatomite, asbestos, glass wool, rock wool, aluminum silicate fiber, the adhesive is composed of single water glass to gypsum (room temperature), cement (room temperature), temperature (high alumina cement), silica sol (high temperature) composite use. The micro silicon powder is the source of the important silicon compound. In addition, a variety of additives are added to improve the properties of the coatings, such as fluidity, hardening, hydrophobicity, high temperature resistance, reflection and so on. Through mechanical beating, foaming, stirring and other technology to make paste thermal insulation paint. Its characteristics are simple production process, can be smeared, convenient construction, good insulation layer integrity. It is especially used for insulation of pipe accessories and equipment such as valves, flanges, three links, balls, cones, rotating bodies and other equipment.

Compared with other thermal insulation coatings, silicate thermal insulation coatings with microsilica have the advantages of the following aspects:

1. It has good stability. Silicate thermal insulation coatings inherit the properties of silicate stability, no dust, no poison, no stimulation to human body, no deformation after use, no corrosion, stable and reliable, and can be applied to different working environments.

2, good decoration, micro silica fume composite silicate insulation coating has good decoration. It is not only suitable for new buildings, but also for repacking old and old walls.

3, the construction is convenient, micro silica composite silicate insulation paint drying has certain compressive strength and bonding strength, non load bearing parts without shell making in construction, change is very simple, without support, the scene painting, do not need a protective layer, without insulation surface shape, thereby saving construction cost. Especially in the special-shaped equipment, the advantages of other thermal insulation coatings can not be compared. Microsilica composite silicate insulation coating is paste, plastic, can be smeared into any shape, no waste material, no shell and sealed.

4. It can be used for hot repair. The composite silicate insulation coating is very convenient for thermal repair without affecting the normal operation of the equipment.